Energy Management /

Sustainability

BLOG NOTE: My apologies! This section needs to be updated. It's on my mind so I'll get to it soon. 1/17/22

One of my favorite pastimes carries over from my days as a building facility manager. In the early 1970s all building systems had manual controls. The closest we came to automation was the use of mechanical timers. Thus, while I managed the 100,000 SF school campus we counted on mechanical timers to turn air handlers on and off while the building temperatures were controlled by analog pneumatic thermostats. The air conditioning and lighting systems were controlled manually.

Each morning the building engineer would walk through the building, turn on the lights, energize the fans, and turn on the boilers for heat or chillers for cooling during the season, with each decision based solely on his intuition.

There weren't a lot of opportunities for energy savings. The large fans and banks of light fixtures were either ON or OFF. Any special schedule would require manual adjustments.

My very first venture into central control was an elaborate time clock with 16 channels of control. We connected all of the large air handlers and major lighting circuits to this super-timer. We were making progress toward more efficient control, but there were still a lot of manual inputs necessary in order to be efficient.

What followed was the reason I like to consider myself an "energy management pioneer": my curiosity (and youth) provided the initiative to build my own controller. The word "sustainability" was not in vogue.

I used an IBM desktop (10 kb hard drive) with a Prometheus card to give me 8 analog inputs (to measure temperatures) and 8 digital outputs (to turn things on and off). This initial arrangement gave me control of four 50-horsepower air handlers and night lighting in the school building. I wrote all of the code for the programming.

As the automated control industry grew, so did my interest in expanding our energy management. We selected targets and accomplished goals. For example, we would might choose to convert every thermostat in the science wing over the winter break. We would order the parts and cable, pre-wire the area for the control network, and then convert all the thermostats and control louvers in the classrooms and corridors and update the programming when the building was unoccupied.

Ten years later, as I turned over responsibility for the building, we were monitoring temperatures in every space and controlling the air handlers and chillers accordingly. The lighting was activated by proximity sensors and exterior lighting was activited according to daylight. The final count totaled more than 150 temperature sensors, a variety of motion detectors, and precise control of the heating and cooling throughout the 100,000 SF building.

Cleveland Botanical Garden

In my three distinct "jobs", energy management was always my focus. But in my final position as Facilities Director at the Cleveland Botanical Garden, the reduction of our energy footprint was the highest priority for me. I loved my work there, and I was determined to lasso in our use of steam, chilled water, and power.

I spent quite a bit of time analyzing our energy use. Although certain financial loans were available to us, our analysis found that we were best if we did things on our own.

First, we converted 120 high-wattage fixtures in the underground parking garage to LED. Next, after receiving expensive quotes from electrical contractors to convert 120 simple ceiling fluorescent fixturers to LED seemed to be out of line, I gave our own facilities staff the incentive to change the fixtures to LED on our own.

The end result: a huge reduction in power usage, a reduction in our carbon footprint, and better lighting for everyone.

Personally, I am proud of my accomplishments and received much support from the millennial-aged staff. It was a great way to end my working career.

JML

___________

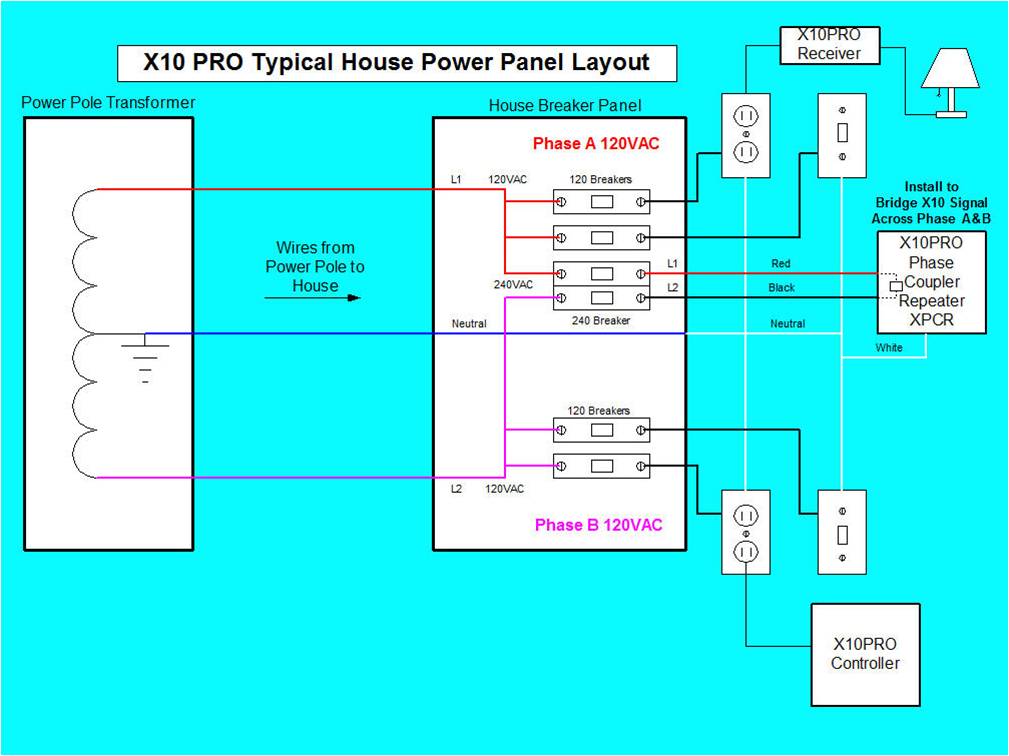

At home, I first experimented with X-10 to control lighting:

www.x10pro.com

www.x10pro.comI was convinced that we all would eventually be using smart controls for our buildings. I never imagined that we could control our homes in a similar way.

___________

Next, I became interested in Arduino:

www.arduino.cc

I've been following the progress of the Arduino control modules. These advanced controllers make a lot of sense to me. Not only could I control lighting, but I would also be able to monitor specific temperatures throughout my house. But quite frankly, while I'm ready to pull the trigger and convert to Arduino I admit that I'm a little intimidated by the progamming.

___________

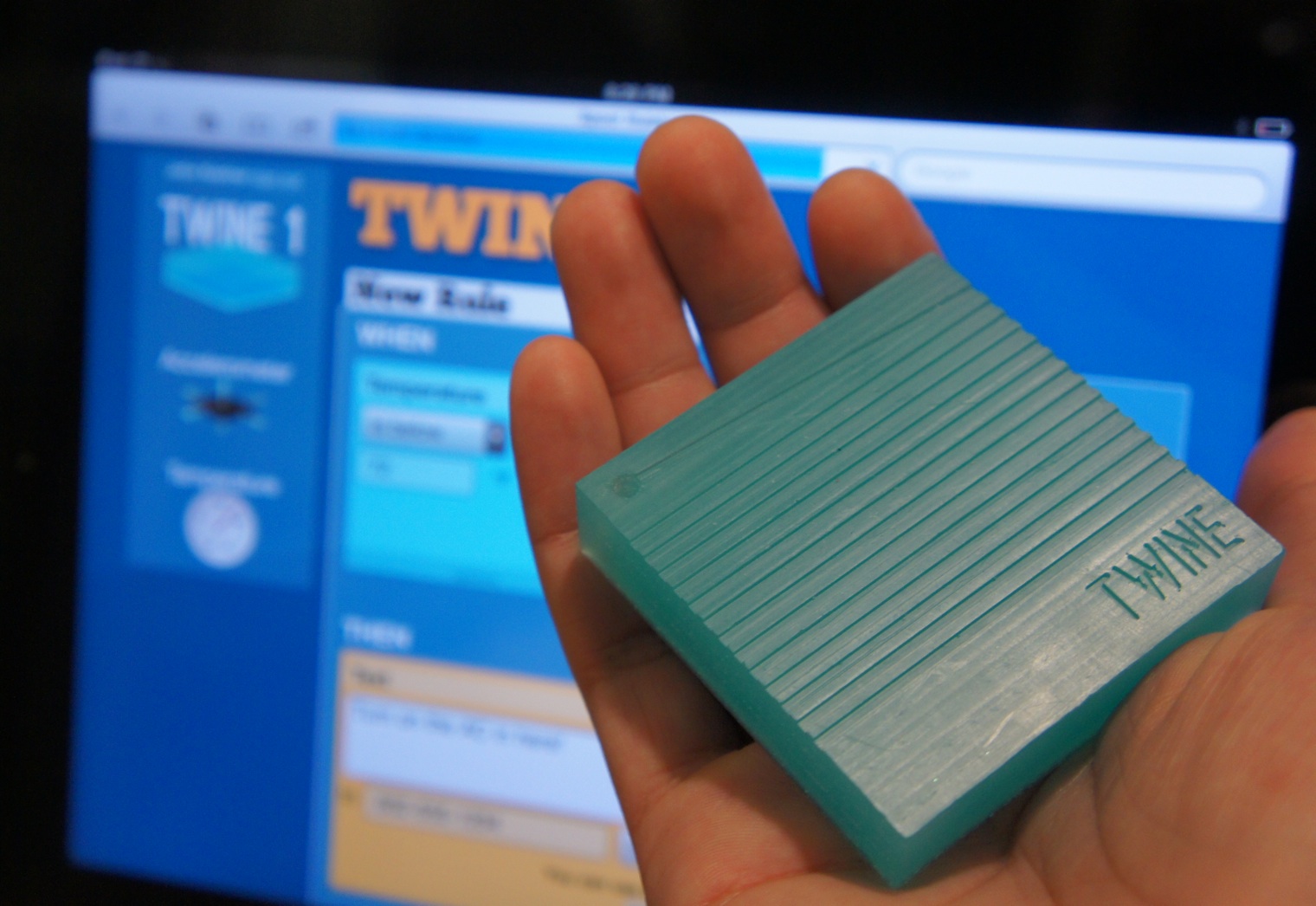

Next, was Twine. It didn't last long:

www.supermechanical.com/twine

www.supermechanical.com/twine

I follow the Kickstarter website, and I was curious-enough about the Twine as to have invested in the build-out costs of a protocol unit. Although I experimented with the Twine unit, I'm not sure why but it lasted just a few years.

Wemo

I used Wemo to control my lighting for more than ten years. But recently I decided that they can be very "quirky," with switches dropping off line at inopportune times. I have a robust Ubiquiti network so there is strong WiFi everywhere in the house, and after much frustration I finally decided to make a change.

LEVITON Smart Switches

In 2024 I converted to Levition Smart Switches. These switches work well with Alexa and Siri and other popular central controllers. There are certain conditions that require a central hub (such as not having a neutral circuit - usually the white wire). All of my exterior lights are on a schedule, and I also make good use of Amazon's Alexa for controlling lights throughout the house as well.

In summary, I just want to emphasize that I fervently believe that everyone can accomplish significant energy reduction in their home. I really enjoy tinkering and tweeking to reduce my use of natural resources. My monthly consumption averages less than 600kw ($85-$100) for my average-sized house.